International Standards Adhesion Strength:

DIN ISO 6133 - ISO 36 - ISO 6133 - VDA 675 226 (withdrawn) - a.o.

International Standards Tear Resistance:

ASTM D 624 - DIN 53 507 (withdrawn) - DIN 53 515 (withdrawn) - DIN ISO 34-1 - ISO 34-1 - ISO 34-2 - JIS K 6252-1 - JIS K 6252-2 - VDA 675 210 (withdrawn) - 675 211 (withdrawn) - a.o.

For tear propagation resistance, our laboratory has the following punching gauges for a wide range of specimens, as well as 3 universal testing machines. Our temperature chamber also allows us to measure tear resistance in a temperature range from -30°C to +150°C:

- Strip specimen (harness specimen), 2 mm and 6 mm

- Angle Test Piece with and without nick

- Crescend Test Piece with and without nick

- Small (Delft) Test Piece

Since the quality and the actual incision depth of the specimens have a considerable influence on the precision of the measurement, we use punching knives with adjustable incision depth for the angle specimen and the crescent specimen. Hereby we guarantee an exact and standard-compliant incision depth for materials from very low to high hardness ranges, according to the most different requirements and standards.

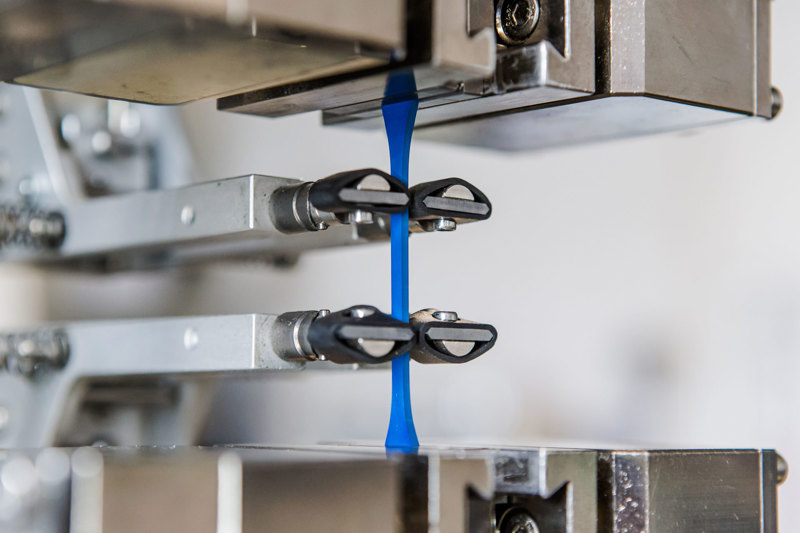

Tear resistance describes the ability of elastomers to counteract progressive crack formation. For this purpose, a standardized specimen with a defined crack initiation, i.e. an artificially introduced defect (indentation) of defined geometry, is placed under tensile load. The energy required to extend the crack by a certain length is measured and specified as tear propagation resistance.

The tear propagation resistance provides information about the material's resistance to crack propagation and is decisive for applications in which mechanical loads and deformations occur.

International Standards Tensile Lap-Shear Strength:

ISO 4587 - a.o.

International Standards Tensile Test:

Elastomers

ASTM D 412 - DIN 53 504 - ISO 37 - JIS K 6251 - VDA 671 002 - a.o.

Plastics

ASTM D 638 - DIN EN ISO 527-1 - DIN EN ISO 527-2 - ISO 527-1 - ISO 527-2 - a.o.

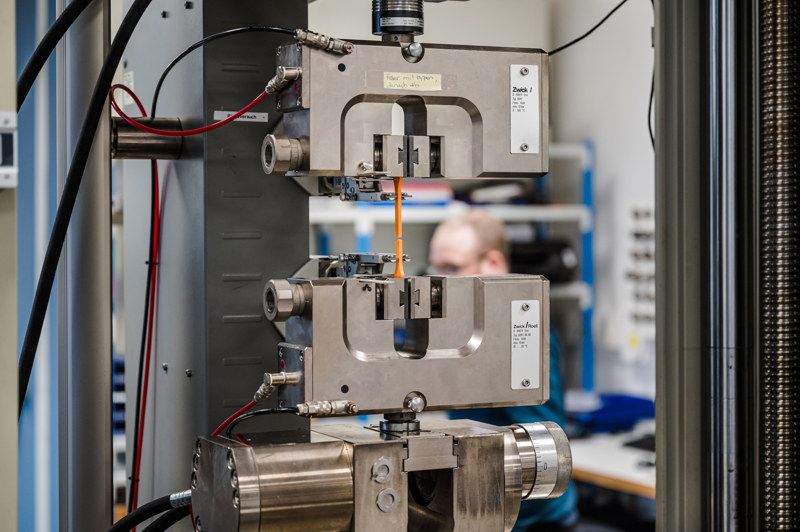

For tensile testing, 3 universal testing machines with load cells in different force ranges are available in our laboratory. We use high-precision clip-on extensometer with the highest resolution, which meet the accuracy class 0.5 (ISO 9513). This enables us to precisely test elastomers, thermoplastic elastomers as well as fiber-reinforced plastics of high strength. Our temperature chamber also allows us to perform tensile tests in a temperature range from -30°C to +150°C in a force range up to 10 kN.

The tensile test on elastomers, thermoplastic elastomers or plastics is an experimental method for determining the mechanical properties of these materials. In this test, a specimen with a defined geometry is clamped in a universal testing machine and stretched in a controlled manner at a constant speed in the longitudinal direction. During the elongation, force and change in length (extension) are measured to determine the stress-strain curve.

This curve can be used to determine parameters such as tensile strength, elongation at break and stress values for elastomers and thermoplastic elastomers at a defined arbitrary elongation. For plastics, parameters such as modulus of elasticity, yield stress, elongation at yield, tensile strength, stress at break and elongation at break can be read off.

The results obtained from the tensile test are material characteristic values and are therefore relevant in the fields of quality assurance, design and calculation, among others.